PDR for steel panels remains vital in construction and automotive sectors due to its ability to repair minor to significant damage, preserving structural integrity and aesthetic appeal. As steel's popularity grows, so does demand for PDR services, offering cost-effective, eco-friendly solutions for both vehicular and architectural repairs while minimizing waste and extending material lifespans.

In 2025, the construction industry continues to evolve with innovative materials and designs. Amidst this transformation, PDR for steel panels remains a pivotal practice, offering both durability and cost-effectiveness. This article explores why PDR is still relevant today, delving into its role in navigating evolving construction trends, enhancing steel panel lifespan through specialized repairs, and ensuring long-lasting structures despite changing times.

- PDR's Relevance in Evolving Construction Trends

- Durability and Cost-Effectiveness: A Lasting Partnership

- Specialized Repairs: Enhancing Steel Panel Lifespan

PDR's Relevance in Evolving Construction Trends

In the evolving landscape of construction, where new materials and technologies are constantly emerging, PDR (Painted Surface Damage Repair) for steel panels remains a vital skill set for several reasons. As the demand for durable, yet aesthetically pleasing structures continues to grow, so does the need for professionals who can expertly handle repairs on these metal surfaces. The use of steel in construction is not just a trend; it’s a cornerstone of modern building practices due to its strength and longevity. Thus, PDR for steel panels is an essential service that ensures these structures maintain their integrity and beauty over time.

In light of the rising popularity of custom designs, architectural nuances, and complex panel configurations, collision repair shops specializing in PDR for steel panels are increasingly sought after. These professionals possess the expertise to address various types of damage, from minor dings and scratches to more significant impact events, ensuring that each panel is restored to its original condition. This level of precision not only preserves the structural soundness of buildings but also guarantees they maintain their market appeal. The skills required for PDR are particularly valuable in urban areas where auto repair shops often cater to both vehicular and architectural needs, providing comprehensive car repair services while contributing to the overall aesthetic of the cityscape.

Durability and Cost-Effectiveness: A Lasting Partnership

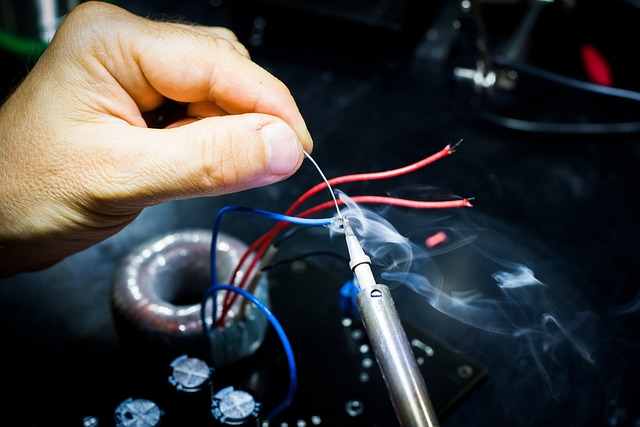

In the pursuit of durability and cost-effectiveness, PDR for steel panels stands as a robust solution that continues to be relevant in 2025. This non-invasive repair technique is not just about restoring the aesthetics of metal surfaces; it’s a strategic partnership between longevity and affordability. Unlike traditional methods that often involve extensive repainting or replacement, PDR focuses on revitalizing the panel’s surface by gently manipulating it, making it an eco-friendly and pocket-friendly option.

The synergy between PDR and steel panels is evident in various sectors, including automotive body shops and fleet repair services. By adopting this approach, businesses can significantly reduce costs associated with car body restoration while ensuring that vehicles retain their structural integrity and resale value. This partnership also contributes to a more sustainable landscape by minimizing waste generated from traditional metal repair processes.

Specialized Repairs: Enhancing Steel Panel Lifespan

PDR for steel panels plays a pivotal role in extending the lifespan of these durable materials used in various applications, from automotive bodies to architectural structures. This specialized technique focuses on repairing dents and dings rather than replacing entire sections, significantly reducing costs and waste. In 2025, as sustainability gains prominence, PDR remains essential for steel panels due to its environmental benefits. By minimizing the need for new materials and energy-intensive manufacturing processes, PDR contributes to a greener approach to collision repair and vehicle body restoration.

Moreover, PDR offers precision and effectiveness in addressing even the most intricate car dent removal challenges. With advanced tools and trained technicians, it can restore damaged steel panels to their original condition, enhancing aesthetics and structural integrity. This process is particularly valuable for automotive manufacturers and owners seeking cost-efficient solutions without compromising on quality or safety, solidifying PDR’s place as a go-to method in the vehicle body repair landscape.

In 2025, as construction trends continue to evolve, the relevance of PDR (Polished Metal Restoration) for steel panels remains undeniable. Despite advancements in materials and technologies, the enduring combination of durability and cost-effectiveness offered by PDR ensures its place as a vital solution for maintaining and repairing steel panel structures. As specialized repair techniques further enhance the lifespan of these panels, PDR for steel panels will continue to be a game-changer in construction maintenance, ensuring lasting performance and aesthetic appeal across various industries.