PDR (Paintless Dent Repair) is a specialized automotive technique for repairing damaged steel panels like those found in car bodies and bumpers, without cutting, welding or painting. Trained technicians manipulate metal with controlled pressure to realign it, preserving structural integrity and aesthetic appeal while offering a cost-efficient alternative to bumper repair or major bodywork replacements. This method is highly favored in modern collision centers for its speed, precision, and ability to reduce vehicle downtime.

In today’s world, maintaining the aesthetics and integrity of steel panels is paramount, especially in industrial and architectural settings. Paint Damage Repair (PDR) for steel panels is a specialized process that addresses dings, dents, and scratches, restoring them to their original condition. This article delves into the science behind effective PDR, exploring the unique challenges of steel’s chemical composition and surface preparation, while offering insights on advanced tools, best practices, and expert tips for maximizing efficiency and durability in repairs.

- Understanding PDR for Steel Panels: The Basics

- – Definition and significance of PDR (Paint Damage Repair)

- – Unique challenges of repairing steel panels

Understanding PDR for Steel Panels: The Basics

PDR for steel panels, or Plastic Deformation Repair, is a specialized technique used to restore damaged car bodies, particularly on steel panels like those found in car bodywork and bumpers. This method involves carefully manipulating the metal without cutting, welding, or painting, ensuring a precise and seamless repair that matches the original factory finish. The process begins with identifying the damage, which can range from minor dents to more significant creases or buckles.

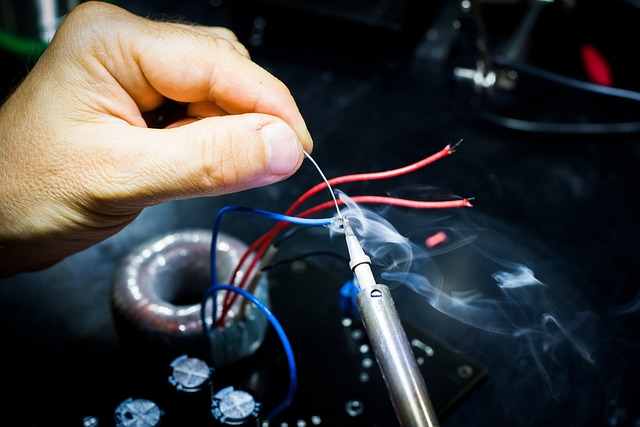

Trained technicians use specialized tools to apply controlled pressure, gradually realigning the metal to its original shape. This non-invasive approach not only preserves the structural integrity of the panel but also maintains the vehicle’s aesthetic appeal. PDR is particularly effective for auto detailing enthusiasts and those seeking a cost-efficient alternative to bumper repair or major car bodywork replacements, making it a preferred choice in the automotive industry.

– Definition and significance of PDR (Paint Damage Repair)

Paint Damage Repair (PDR) is a specialized technique used to restore and refinish damaged automotive surfaces, particularly on steel panels. It involves the skilled manipulation of various tools and methods to remove dents, scratches, and other imperfections without compromising the original finish. For steel panels, PDR is especially significant as steel is a commonly used material in vehicle construction due to its strength and cost-effectiveness. Proper PDR not only enhances the aesthetic appeal but also preserves the structural integrity of the panel, making it a valuable service for both collision repair centers and body shop services.

In the world of car body repair, PDR offers numerous advantages. It is a cost-efficient alternative to painting the entire panel, reducing waste and saving time. Additionally, PDR allows for precise repairs, ensuring that only the damaged area is treated. This meticulous approach not only maintains the vehicle’s overall value but also contributes to a faster turnaround time compared to traditional collision repair methods. By employing PDR techniques, skilled technicians can effectively revitalise steel panels, giving them a like-new appearance without the need for extensive bodywork or replacement parts.

– Unique challenges of repairing steel panels

Repairing steel panels presents a unique set of challenges for professionals in the automotive industry. Unlike other materials, steel is prone to deformation and denting, which can be difficult to reverse without leaving permanent marks or compromising the structural integrity of the panel. The process of PDR (Paintless Dent Repair) for steel panels requires specialized techniques and tools to address these issues effectively.

In a collision center or body shop setting, where speed and precision are paramount, mastering PDR for steel panels is essential. Unlike traditional repair methods that often involve extensive welding and painting, PDR offers a more efficient and cost-effective solution, preserving the original finish of the panel while ensuring structural repair. This not only reduces the overall cost of repairs but also minimizes downtime for vehicle owners, making it a preferred choice in modern automotive repair services.

In conclusion, understanding the science behind PDR for steel panels is key to achieving superior repair outcomes. By grasping the intricacies of the process and the unique challenges posed by steel’s properties, professionals can deliver top-quality work that enhances the aesthetics and longevity of these structures. This article has provided a foundation for effective PDR for steel panels, empowering readers to navigate this specialized field with confidence.